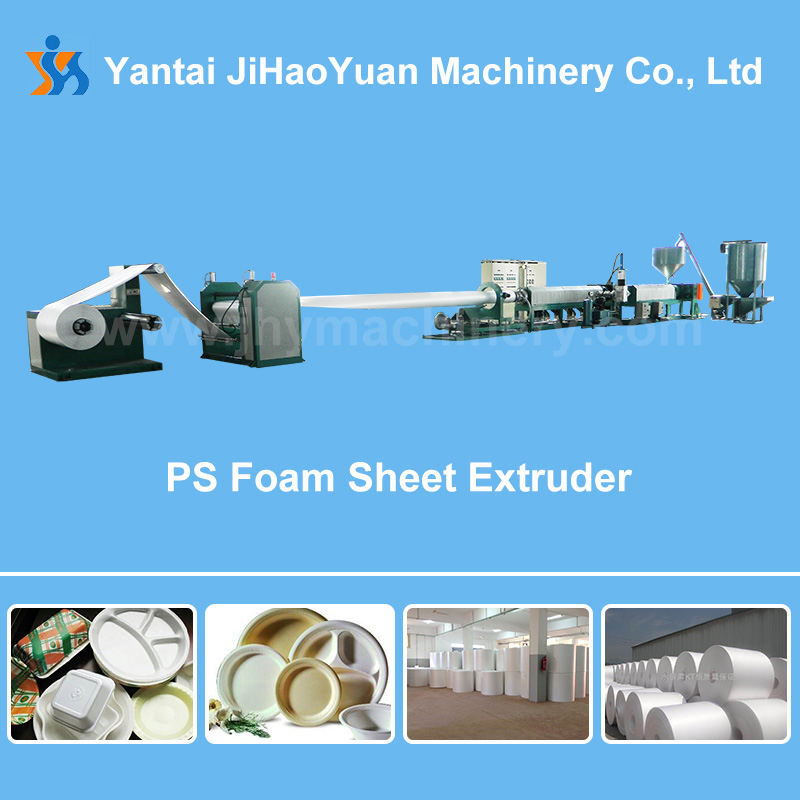

PS-PE Recycling Machine

Introduction

This design recycling machine is double screws and it can make the recycled material be better than single screw recycling machine. Because it can filter first and heat longer time to make liquid material at a better state to get better quality granules. And its capacity is larger than single screw recycling machine because two screws can enter more liquid material inside.

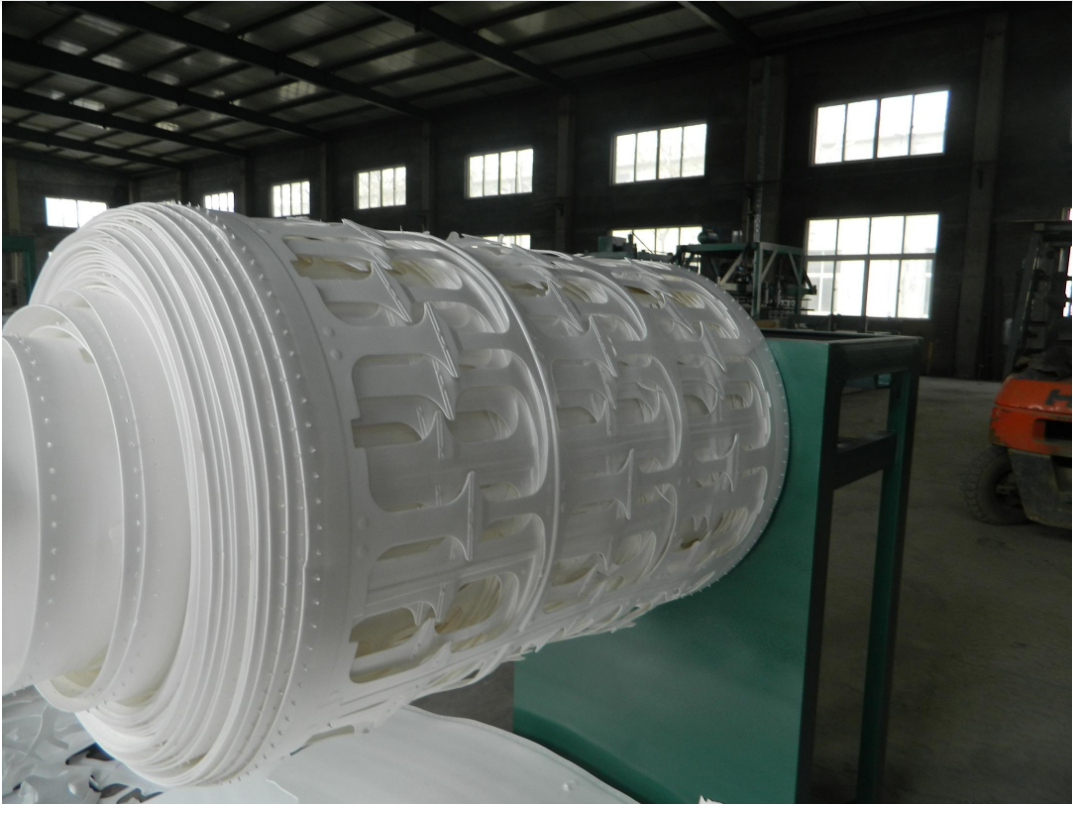

The ps waste scraps are mainly from your own fully automatic ps foam food box thermoforming machine last part or the semi-automatic ps foam food container thermoforming machine with cutting off machine for more scraps and also the not good products. All these scraps are generated from the thermoforming machine and it will be clean in your food box production plant.

Robot design food box thermoforming machine, tear apart design lunch box thermoforming machine and the semi-automatic fast food box thermoforming machine has 10-15 %waste ration and the stacking design food dish forming machine has 20% waste ratio. If we leave it away, it will be a waste and also not good to the environment.

So the recycling machine will be a good choice for reusing it.

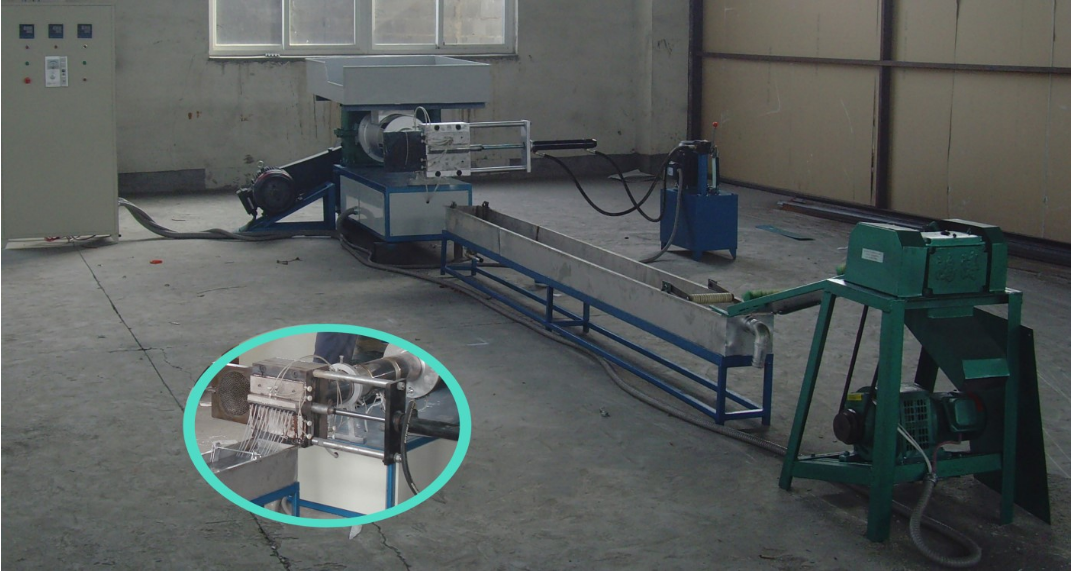

We just need to crush all the waste scraps to be small scraps and enter into the recycling machine hopper, it will become liquid again and extruded as like noodles. After cooling and cutting, we can get the granules again.

Because there is rule for food box, food tray etc. about the food grade and clean material. So we can use the recycling material to make egg tray, egg box, fruit tray, vegetables tray, drugs tray and the cosmetic tray etc. Because these trays are not for people eat and there is no too much requirement and it can be used for packing better.

Component

A. Hopper for crushed waste small scraps

B. 1#extruder for heating the scraps to be liquid state

C. Filter changer manual design to filter the impurities of the waste scrap material.

D. 2#extruder to heat the liquid state material to be a good quality

E. Mold to extrude the liquid material as like noodles

F. Water tank to cool the liquid noodles material to be hard

G. Brusher to clean the water of the hard noodles’ material

H. Rolling Cutter to cut the hard noodles to be small granules and pack it to box.

Techanical Data

| Technical Parameter | Unit | ZLS-150/120 |

| 1#Extruder Diameter | MM | Φ150 |

| 2#Extruder Diameter | MM | Φ120 |

| Power | KW | 42 |

| Capacity | Ton | 4-5T/24Hour |

| Installation Dimention | M | 6X3X1.5 |

| Weight | Ton | 2.5 |

| Power Supply | 380V50HZ(3Phase 380V 50HZ) | |

Working Flow

Product Details Pictur