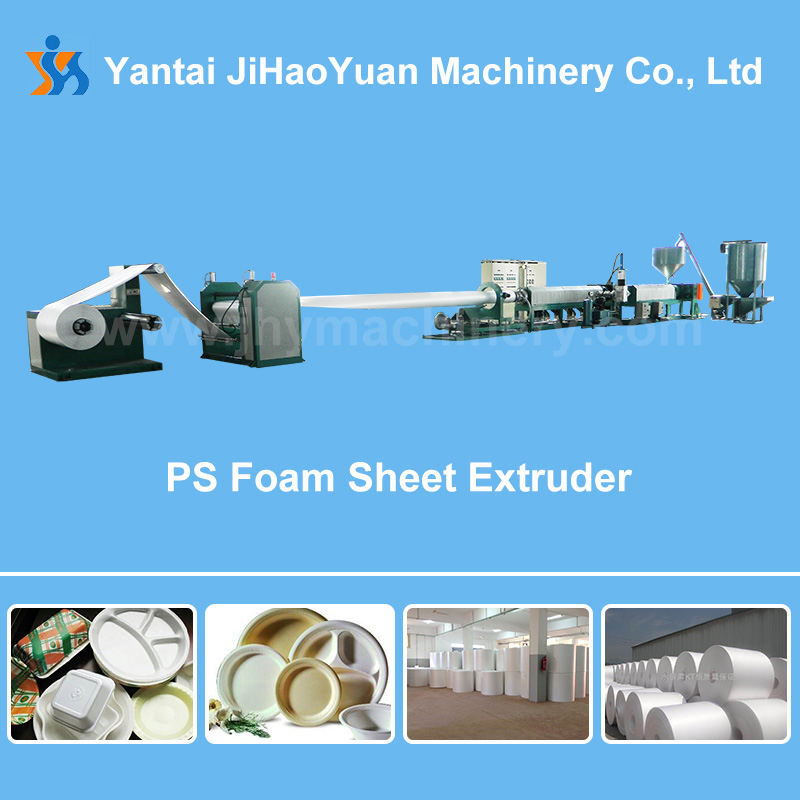

PS Foam Fast Food Box Thermoforming Machine

PS Foam Fast Food Box Vacuun Forming Machine is an all-powerful thermal forming machine. It adopts digital system,fully automatic PLC mechanical and electronic integeration control,touch screen to control the working programme.It is easy yo operate with high effiency.It features reliable stablity, easy operating and good cutting accuracy.It can be used to produce different food box, food tray, egg tray, burger box and pizza tray etc.

Component & Function

A. Feeding Unit: It is used to load the ps roll for feeding. There is switch to press the ps roll so that we ca n control the ps roll not rolling too much.

B. Heating Oven: There are many Far Infrared Heating Tiles inside the oven to control the temperature and there is one pressure controlled button to push the oven out. Once the power off, we can push the oven out so that the ps roll inside can not be heating too high and get fire.

C. Forming Unit: There is mold inside and it is easy to change the mold so that we can produce different type food box, food tray etc. There in only forming unit at semi-automatic machine. So we need another cutting off machine to assist and get the final products.

D. Hydraulic Station: It is for forming unit and cutting off unit.

E. Temperature Cabinet: There are two Temperature cabinet. One is for upper and one is for the bottom. All the temperature will be showed on the screen and we can adjust the temperature according to the products.

Control Cabinet: It is the Brain of the machine. It is used to control the machine all part running. There is PLC Control and Screen will show you all the program.

Techanical Data

Technical Parameter | Unit | ZLS-Semi-640/850 | ZLS-Semi-1100/1250 |

Forming Area | MM | 640X850 | 1040X1250 |

Forming Depth | MM | 130 | 130 |

Production Efficiency | Sec/Die | 3-8 | 3-8 |

Installation Dimention | M | 13X2.5X2 | 15X3.5X2.4 |

Installed Power | KW | 80 | 160 |

Power Supply | 380V50HZ(3Phase 380V 50HZ) | ||

Product Details Picture