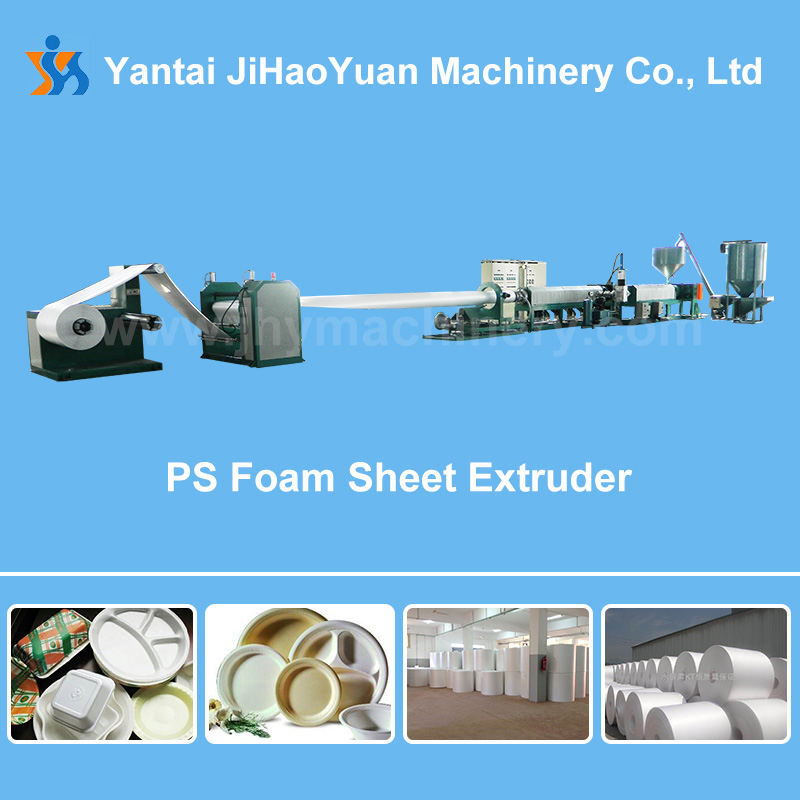

PS Foam Fast Food Box Thermoforming Machine

PS foam fast food box hot forming machine tear edge is a modified style of blanking. In accordance with the use requirements of our customers and in view of the blanking hot forming machine itself shortcomings (produce more scraps, light products, in blanking, easy to float and confusion, not convenient counting and packaging), we remove the blanking part of the equipment, add crosscutting knife, directly cut off the completed molding and blanking sheet, and then manually tear off the corners, to get the finished product.

The advantage of the edge is that the residual material is reduced to 10% from 25% of the blanking, and the finished product rate is higher. It is suitable for the relatively cheap artificial countries.

Component & Function

A. Feeding device: used to load ps roll for feeding. Sensor control ps volume length does not feed too much.

B. Heating box: There are many far-infrared heating tiles inside the oven to control the temperature, and there is a pressure control button to push the oven out. Once the power is off, we can push the oven out so that the ps rolls inside don't heat up too much and catch fire.

C. Molding unit: internal mold, easy to replace the mold, can produce different types of food boxes, food trays, etc.

D. Blanking device: This device is mainly used to cut ps foaming products into a single, and then take all unit products out of the packaging.

E. Cutting device: This part is mainly to cut the total sheet material formed by ps, and then collect all the sheet material into one place, tear the unit food box/tray/plate and pack it into a plastic bag.

F. Hydraulic station: Used for forming unit and cutting unit.

G. Temperature cabinet: There are two temperature cabinets. One is upper and one is lower. All the temperatures will be displayed on the screen and we can adjust the temperature according to the product.

H. Control cabinet: It is the brain of the machine. Used to control the operation of various parts of the machine. PLC control, screen display all programs.

Working Flow

上料Loading PS Foam Roll——片材进入成型机PS Roll Enter into Forming Machine——预热Preheating——加热Heating——成型Forming——冲裁Cutting Off——切断Cut——撕边Tear Apart Scrap——包装Packing

Product Details Picture