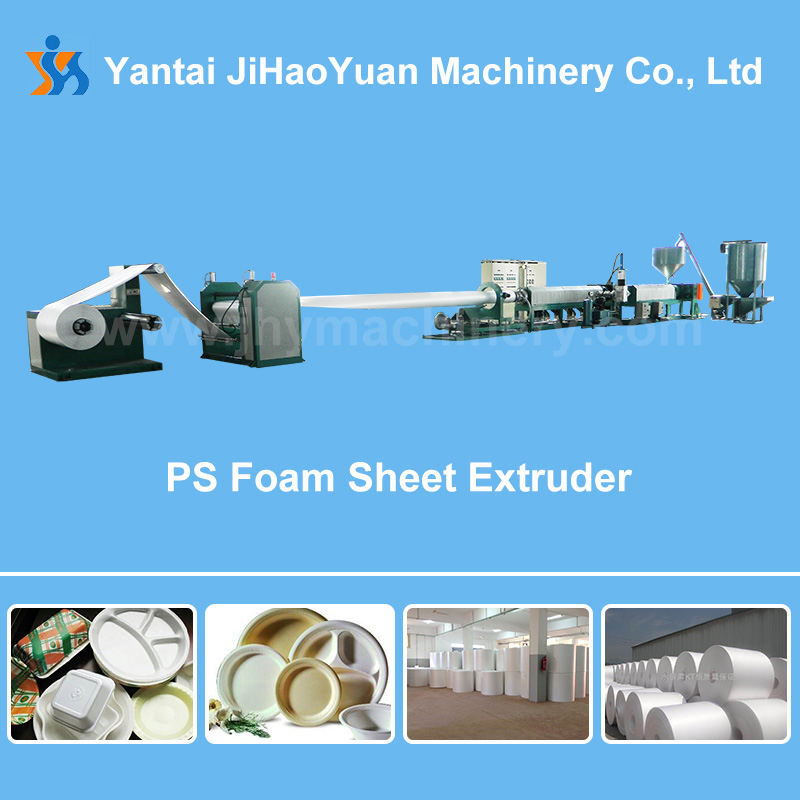

PS Foam Fast Food Box Thermoforming Machine

This machine is all-powerfull thermoforming machine with integrating vacuum forming,cutting off,stacking and counting, consist of those parts as below:

Loading part-heating part(three heating zone)-forming part-cutting off part- double workstation mechanical hand part-winding part for scraps(or crusher in line) - double station conveyor part,

The machine with great dependable stability, integrates the forming,cutting off, and stacking as well as the conveyor at the same time.

This machine is much convenient for operator as the humanly design. In addition, is has the feature of the bigger forming area.faster speed for forming and highly automation.

The products will be collected with the stacking parts and vonveyed automaticallywia conveyor. The scraps will be winded or crushed in line.

The more energy will be saved, the safety of the operatorwill be enhanced,and the cost of the running machine will be economized.

As the performance of PS foam sheet,such as strength, stretch and heating resist,will be favorable for the forming in the low temperature setting. The heating part of the machineis designed to be three heating zone control, the temperature of which is from low to high, in order to make the products perfect.

There is hydraulic station used for the forming and cutting off parts as the driving, with the feature of big molds punch power and higher speed.

And the cutting off board could be moved forwarder or back (electric adjustment)to meet the actual needs of different mold.

The knife molds could be micro-adjusted to get the accurate cutting.

The mechanical hand of the machine could be adjusted to move up and down,front and back(electric adjustment) to meet the different needs of molds with various size. And the suction cups of the mechanical hand could be added or reduced as the real operations to meet the needs of final products.

Techanical Data

Technical Parameter | Unit | ZLS-MH1100/1250 |

Forming Area | MM | 1040X1250 |

Cutting Off Height | MM | 160 |

Production Efficiency | Sec/Die | 3-6 |

Installation Dimention | M | 15X5X2.5 |

Installed Power | KW | 180 |

Power Supply | 380V50HZ(3Phase 380V 50HZ) | |

Working Flow

Product Details Picture