Paper Pulp Molding Egg Tray Machine

Our company and the APVC LTD from UK together design and make the pulp molded egg tray machine. In September, 2015, we had already put one production in Texas, America.The company name is Purple Pulp Inc. And currently we are preparing to produce the other six production lines and put all in the United States Of the different cities to meet the requirements of the market, saving transportation costs, thereby reducing product costs.

The specifications of the pulp molding line are many models according to different customer preferences,

market requirements, labor costs, energy costs, field availability and climate in different areas.

With this in mind, in order to meet the different requirements of different countries in the world for the production of paper products, our company manufactures different types of equipment to meet the different requirements of equipment quality to meet the investment cost, thus occupying the market. from samll to large and then successful, we will produce different materials (304 stainless steel or ordinary steel) equipment in order to supply the global market.

Our paper pulp molding machine can be used to produce egg tray/box(6cavities, 10 cavities, 12 cavities, 6+6 cavities,18 cavities, etc.),fruit trays (apples, pears, tomatoes, etc.) ,cup holder (4pcs or 6 pcs), and different industrial products tray etc.

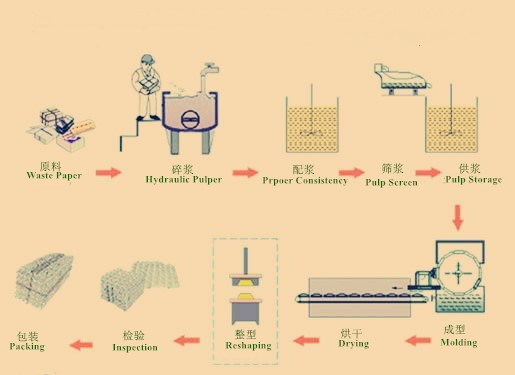

Pulp molded products are made from waste paper, such as waste paper, waste cartons, paper mills and scrap in printing plants.

Adjusting to a certain consistency in the hydraulic pulper and adding some chemicals, the pulp fibers in the vacuum under the effect of covering mold screen, get wet products and then use the dryer to get dry products.

The main raw material is waste paper, which can be easily collected at low cost, and the water used in production is recycled, with little water consumption and no pollution gas emissions in the production process.

Details of egg tray machine

1) Pulp making system: The pulp making system is mainly composed of hydraulic pulper, slurry pump, multifunctional refiner, mixer, control cabinet and so on.

2) Molding system: This is mainly use aluminum mold to finish absorption of pulp, and then through the vacuum pump to finish vacuum suction of pulp slurry to get egg tray or other paper products.

3) Drying system: we can produce single-layer drying lines and multi-layer drying line according to customer requirements. Burner heating and drying, the main raw material consumption of burner is electricity, coal, natural gas or diesel. Customers can choose to use electricity or natural gas at local prices.

4) Packaging system: including stacking system and automatic counting system to facilitate the packaging of finished products.

Working Flow

Product Details Picture