EPE Foam Sheet(Film) Extrusion Line

EPE Foam Sheet Production Line Introduction

Polyethylene(EPE) foam Sheet, also named as Pearl Cotton. It’s a kind of new –type packing material with the features of damp proof, shock proof, sound insulation, heat preservation and good plasticity. It is an ideal substitute of traditional packing materials, and widely used in the packing of fruit, instruments, bags & luggage, shoemaking, household appliances, electronic product, hardware, furniture, fragile goods, etc. Features of this extrusion line: reliable quality, high output, low maintenance, high automation, easy handling with reasonable price.

EPE foam machine can make foam sheet with different width and thickness according to customer requirement. Meanwhile, it can also make foam pipe, foam net, foam rod, foam profile and so on by changing mould and some machine parts.

The foam sheet has the features of dampproof , shockproof, soundproof, heat preservation and good plasticity. After laminating, the foam sheet will get high dampproof performance. These products are mainly used for placing under floor.

Features of EPE Foam Sheet Production Line

1. Automatic feeding material, equipped with automatic alarm system when lack of raw material

2.The cool method adopt air cooling & water cooling. The control of the temperature is steady and exact. The temperature is dropped quickly.

3. The filter changer system has two holes no stop, no cut off material. Automatic hydraulic screen changer, save time, can increase production to 10%.

4. Machine head control adopt diaphragm-type pressure gauge, guarantee the quality of sheet is steady.

5. The winding can be automatically changed over and the length can be fixed by automatic counting.The longest width of rewinding can be 2.8m

6. There is an explosion-proof electric machine beside the butane gas pump to ensure the safety.

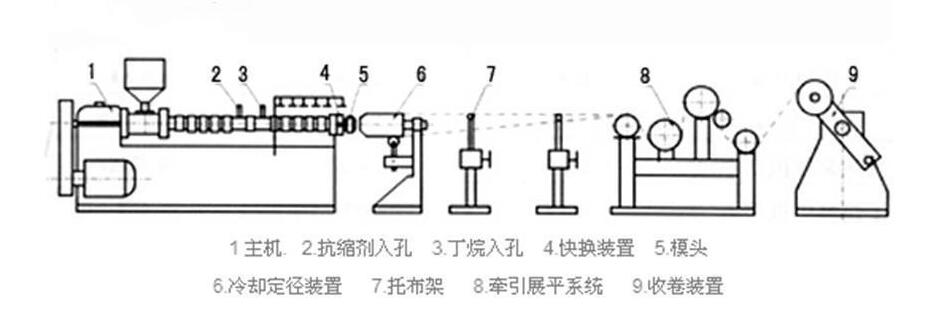

Principle of EPE Foam Sheet Production Line

The L/D of screw is 55 : 1. The raw material is high pressure and low density polyethylene(LDPE) Granules. Through extruding system basis on formula of the raw material and the auxiliary material are transported into hopper by auto feeding system. The GMS will be injected into barrel by the pump as anti-contractor agent . Butane pump inject the liquid butane into the screw barrel and foam .The temperature is dropped by the water and air cooling system then the products will be extruded from the machine head . Fixed and cooled by shaping drum then after processed by expanding system ,haul-off system and winding system . According to the demand for length by customer, automatically warned by meter counter, and then change rolls automatically .After make record of the weight and packed can be delivery to the warehouse.

Techanical Data

| Main Technical Parameters of EPE Foam Sheet Extrusion Line: | ||||||||||||||||

| Model: | ZLS-EPE-90 | ZLS-EPE-105 | ZLS-EPE- 120 | ZLS-EPE-150 | ZLS-EPE-170 | |||||||||||

| Extruder: | 90/55 | 105/55 | 120/55 | 150/55 | 170/55 | |||||||||||

| Screw speed: | R/Min | 5-45 | ||||||||||||||

| Foaming Ratio: | 10-40 | |||||||||||||||

| Product width: | MM | 800-1600 | 1000-2000 | 1000-2000 | 1000-2000 | 1000-2000 | ||||||||||

| Product thickness: | MM | 0.5-3.0 | 0.5-5.0 | 0.8-8.0 | 1.0-10.0 | 2.0-15.0 | ||||||||||

| Cooling Method | Air-cooled, water-cooled | |||||||||||||||

| Installed Power | KW | 90 | 100 | 120 | 150 | 180 | ||||||||||

| Dimension: | M | 20×2.3×2.2 | 23×2.3×2.2 | 25×2.3×2.2 | 30×2.3×2.2 | 32×2.3×2.2 | ||||||||||

| Weight: | Ton | 6 | 8 | 12 | 15 | 17 | ||||||||||

Working Flow

Product Details Picture