EPE Foam Sheet Thickenning Machine

Introduction

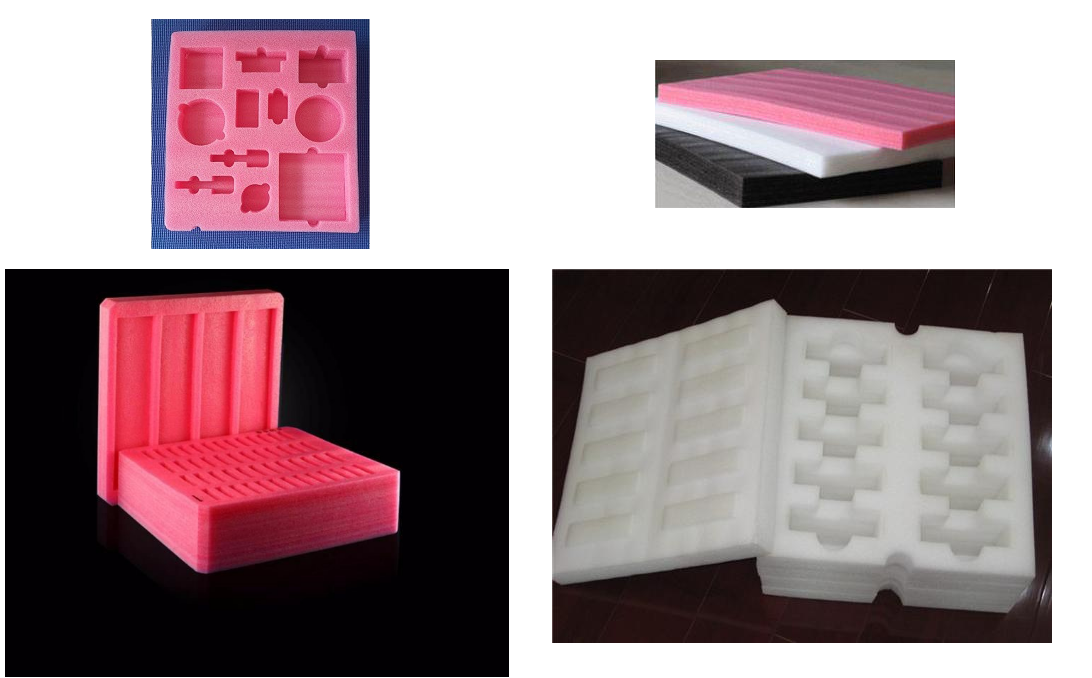

EPE thickening machine is mainly used for thickening the bonding of EPE foam sheet (film). The thickened foam sheet (film) can increase its strength and increase the corresponding thickness. It is widely used in the packaging of furniture, vegetables, fruits, positioning packaging of electronic products, flooring, floor heating and other fields.

This machine is mainly used for the composite thickening of EPE foamed sheets, that is, two or more layers of sheets are melt-bonded to achieve the purpose of increasing the thickness. The composite products are mainly used for electronic products, glass and ceramic utensils and bags. industry. This machine has reasonable structure, high production efficiency and simple operation. It is an ideal equipment for producing thick materials.

Technical Parameters

Product width: 1000-2000mm

Heating method: hot air heating

Total power: 26KW

The company has been supplying pearl cotton thickening machines for many years. If you want to buy pearl cotton thickening machines or if you want to buy pearl cotton thickening machines, we have established long-term cooperation with many companies based on the principle of "customer first, integrity first" relationship. Sincerely welcome friends from all walks of life to visit, inspect and negotiate business. Welcome to inquire, we will provide you with sincere service.

Features

1. The heating box is constructed of stainless steel and will not be deformed when heated. Does not rust. The wind blown by the fan is evenly distributed through the distribution box, and the hot air is blown out from the small holes at the upper end through the hot box, so that the surface of the pearl cotton sheet is melted, and it is squeezed by the stick to stick together.

2. The grinding process of the hot composite steel roller makes it convenient and quick to thicken the finished product.

3. The electronic automatic constant temperature device ensures a constant temperature in the heating box.

4. Pneumatic system design is precise and stable.

Product Details Pictur